High-beat movements, or calibers that run at 36,000 beats-per-hour/10 beats-per-second, are relatively uncommon in the industry today. The prevailing standard for quite some time now has been 28,800 beats-per-hour, or 8 beats-per-second, and it’s for good reason. These movements strike an excellent compromise as far as overall performance is concerned, with 28,800bph calibers being capable of excellent timekeeping without undue wear and tear on components.

Nevertheless, high-beat movements are exceptionally cool and come with two notable advantages. The first is aesthetic — higher-beat movements feature second hands with a smoother sweep. Advancing at 10 beats-per-second, a high-beat second hand glides elegantly across the dial, further masking the start-stop operation of the escapement which one can still make out in slower rate movements.

The second advantage is greater reliability. Ultimately, a balance operating at a faster beat rate will show greater resilience to external rotational forces, like sudden shocks, which in turn results in more reliable daily timekeeping.

But as I briefly mentioned into above, higher-beat movements are not without their downsides, chief among them a decreased power reserve and increased wear and tear on components. So when Grand Seiko approached their modern high-beat movements,, which they call “Hi-Beat,” these concerns were top of mind. Ultimately, by employing state of the art manufacturing processes to ingenious architecture, Grand Seiko’s engineers were able to devise modern Hi-Beat movements that are beautiful, hard wearing, and reliable.

Let us take a closer look at Grand Seiko’s Hi-Beat mechanicals, starting with the all-important mainspring.

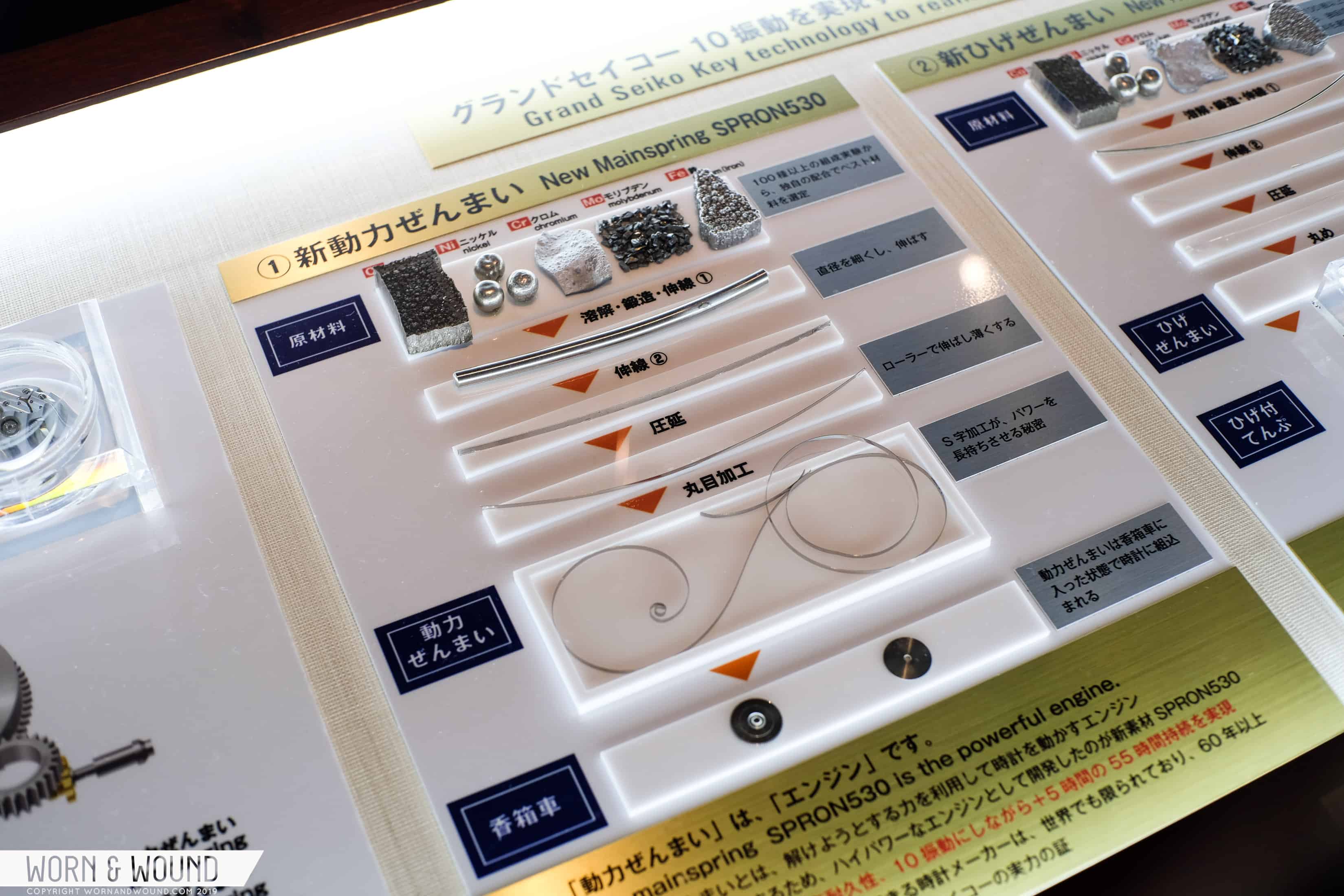

Grand Seiko’s engineers needed a special type of mainspring with 1.5 times the torque of your standard mainspring. Grand Seiko works with a proprietary metallic alloy they call Spron, and for their purposes here they developed a special reinforced variant dubbed Spron 530. This mainspring has the right amount of torque needed to achieve the higher beat rate, and it also manages a higher-than-average power reserve of 55 hours, also notable because higher-beat movements naturally consume more energy.

“Ultimately, a balance operating at a faster beat rate will show greater resilience to external rotational forces, which in turn results in more reliable daily timekeeping.”

Speaking of energy consumption, this is where MEMS comes into play. Now, if you’re at all familiar with Grand Seiko, you may have heard of MEMS without truly understanding what it is and why it’s important. So without getting overly technical about it, MEMS stands for Micro-Electro-Mechanical Systems, and it’s essentially a highly advanced manufacturing process Grand Seiko brought over from the production of semi conductors. Grand Seiko uses MEMS to fabricate certain precision metal parts for their 9S movements, and through this process they’re able to achieve structures that would otherwise be difficult to produce through traditional machine cutting. Additionally, parts produced via MEMS feature smoother surfaces, which minimizes friction, a major source of energy loss inside a movement.

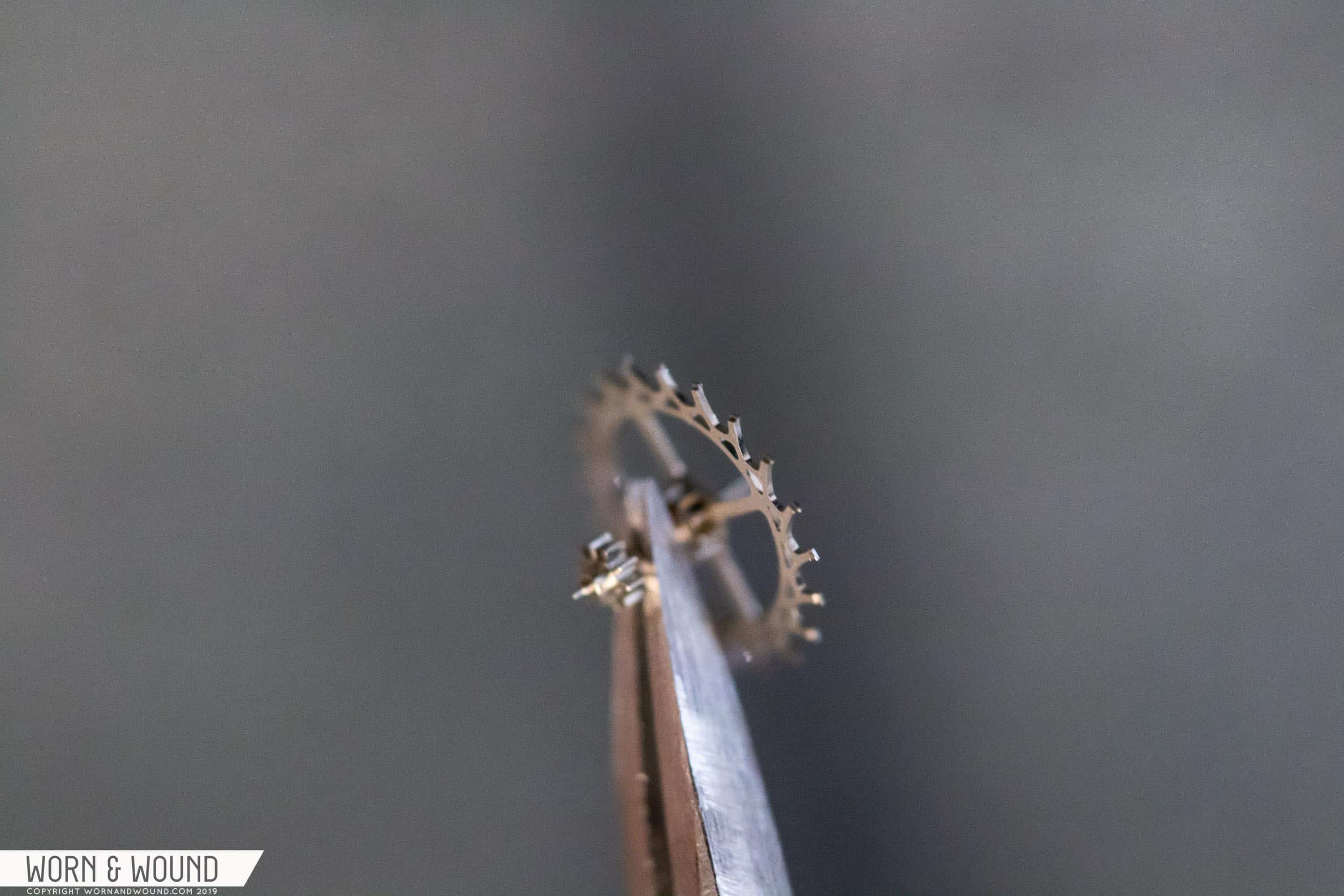

Two components Grand Seiko produces with MEMS are the escape wheel and the pallet fork. Through MEMS, Grand Seiko makes skeletonized escape wheels that are 5% lighter and pallet forks that are 25% lighter than their conventional counterparts. Furthermore, to address the higher degree of wear and tear sustained by hi-beat calibers, these parts are engineered for the purposes of better oil retention. If you look closely at Grand Seiko’s escape wheel, you’ll notice that in addition to the unique skeletonized structure, the cogs feature L-shaped tips designed to better retain lubricant for a longer period of time.

Комментариев нет:

Отправить комментарий